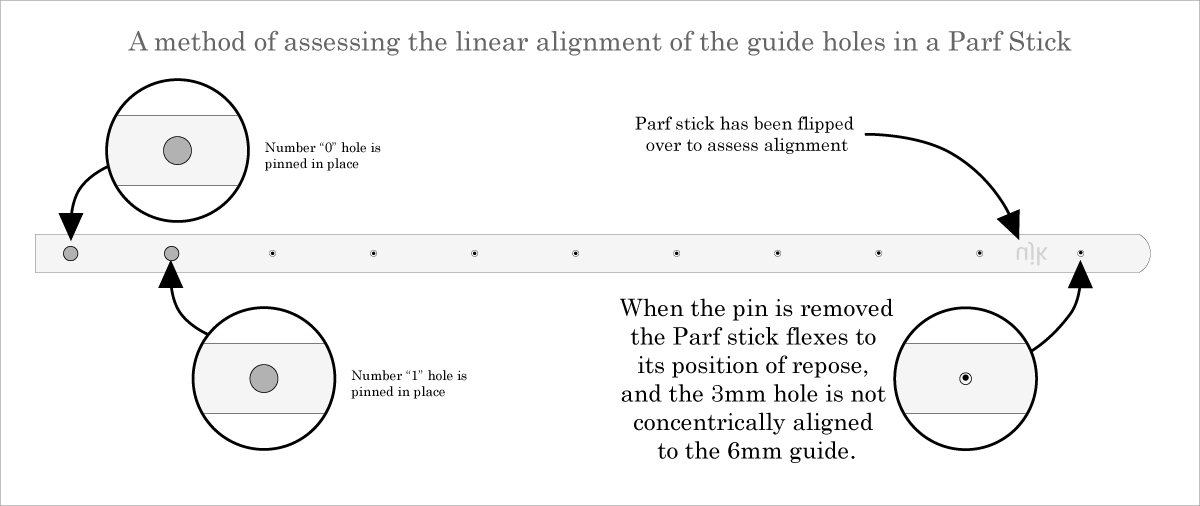

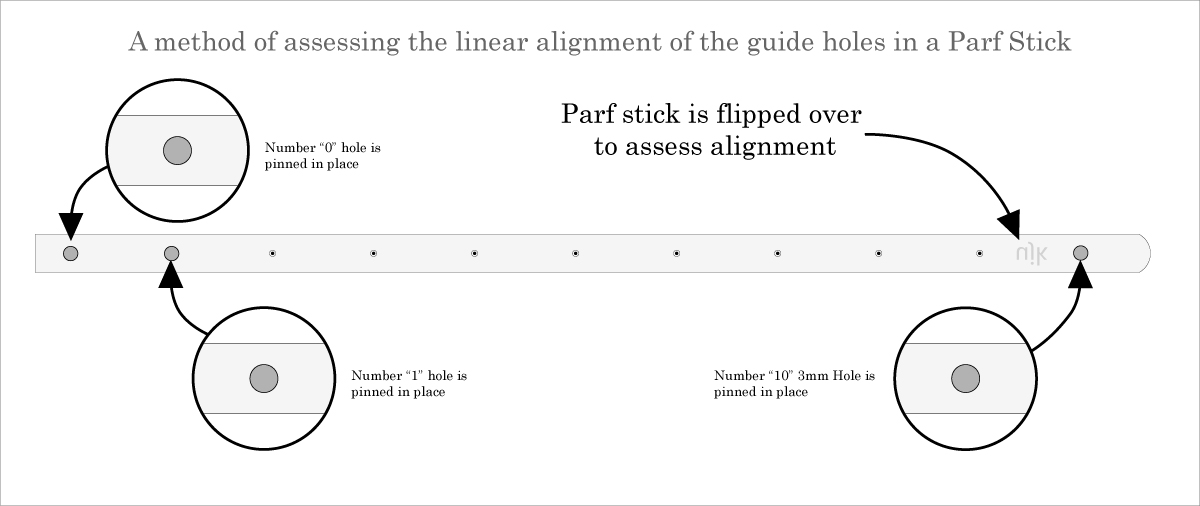

This is a basic method to determine if the holes in a Parf Stick share a linear axis.

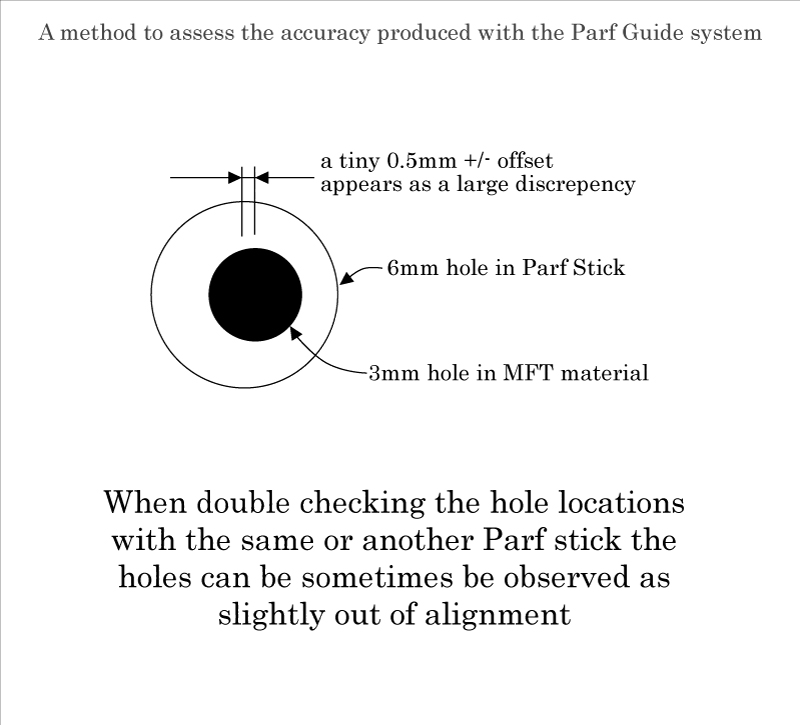

None of the four Parf Stick which I have sampled at my workshop seem to have a set of holes that are aligned precisely. The following notes describe a method that I have used to investigate the cause and demonstrate the results.

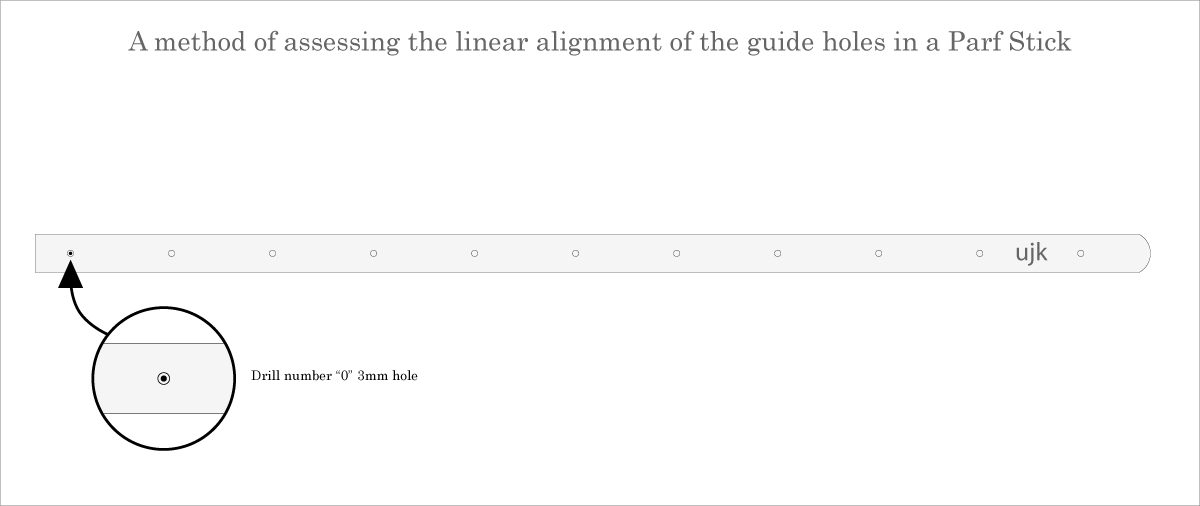

1) Lay the Parf Stick on the table top surface and drill the first 3mm hole.

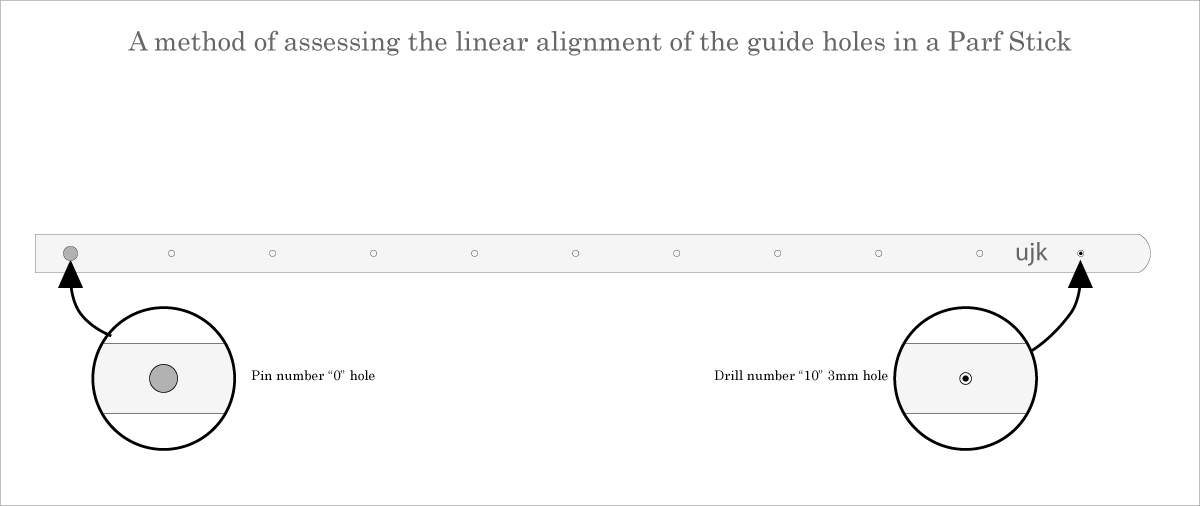

2) Place a pin in hole number "0", and drill the 3mm hole at hole number "10"

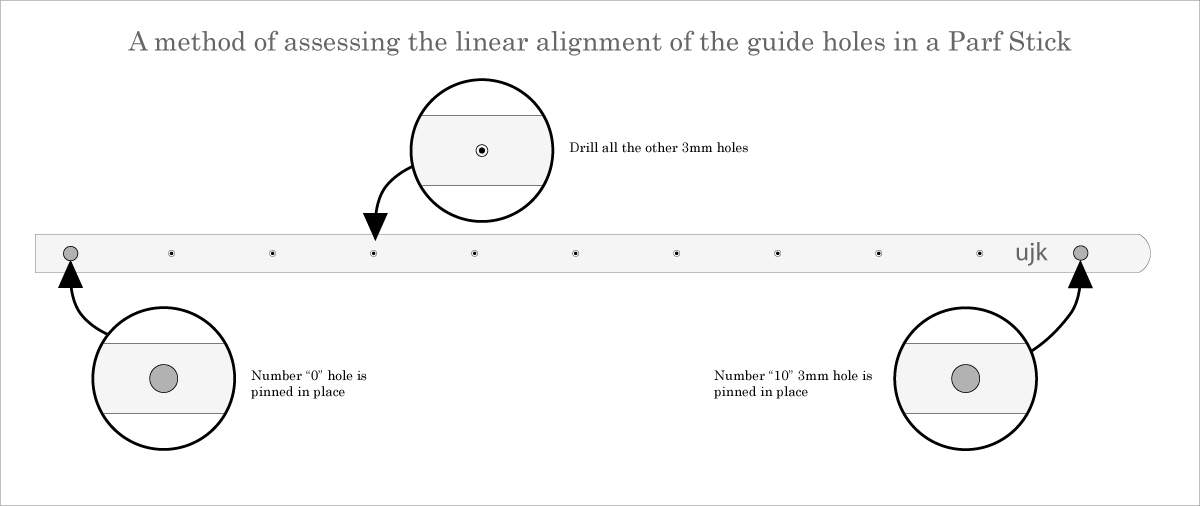

3) Keep the pin in hole number "0", Place a pin in hole number "10", and drill the rest of the 3mm holes. Observe, confirm, and appreciate that the holes appear to be precisely located within the center of the guide holes.

4) Flip the Parf stick over and insert pins at the number "0", "1", and "10" holes. You may find that the third pin fits tightly when it is inserted. This reaffirms the impression that the hole placement is precise.

5) Remove the pin from hole number "10" and watch the end of the Parf Stick slide laterally to its natural, at rest position. A misalignment is revealed and it is apparent that the the guide holes are not aligned on a linear axis. When placing the pins, the Parf Stick is flexible enough to be sprung into line so that the guide holes appear to be centered with the drill holes, but when the Parf Stick lays in repose the presumption that the guide holes are placed on a linear axis can not be relied upon.

Please note that misalignment can be observed, in varying amounts, when the pin used in hole number "1" is removed and placed elsewhere along the array. The anecdotal use of the pin in hole number "1" is simply a particular circumstance that I observed just prior to writing these comments.